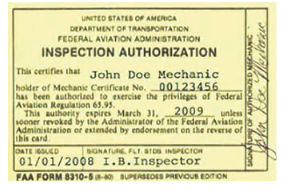

The Airframe & Powerplant (A&P) mechanic is an Aircraft Maintenance Technician (AMT) certificated by the FAA based on personal knowledge gained through training and experience, which is demonstrated by successful completion of written, oral, and practical tests.

When seeking maintenance services for your aircraft, you cannot be guaranteed that every shop has FAA-certified A&P mechanics. At Phoenix Air General Aviation, we are proud to announce that, with the exception of administrative and apprentice positions, every mechanic who performs maintenance on your aircraft will hold their FAA-certificated A&P ratings.

The basic functions of the holder of an Inspection Authorization (IA) are set forth in Title 14 of the Code of Federal Regulations (14 CFR) Part 65, § 65.95. With the exception of aircraft maintained in accordance with a Continuous Airworthiness Maintenance Program under Part 121, an IA may inspect and approve for return to service any aircraft or related part or appliance after a major repair or major alteration. Additionally, the holder of an IA may perform an annual inspection and may supervise or perform a progressive inspection.

Phoenix Air General Aviation is proud to have four A&P mechanics with an IA rating on staff, with several other mechanics currently studying for the rating exam. This enables us to offer you, our customers, confidence in our ability to determine airworthiness, ensure conformity to approved data, and assuring that your aircraft is in a condition for safe operation.

Technicians who repair avionics equipment in aircraft will need a high-level certification called the General Radiotelephone Operator License (PG) or GROL. This license is required if the work involves maintaining, repairing, or supervising any aircraft or ground station used in aviation.

When seeking maintenance services for your aircraft, you cannot be guaranteed that every shop has FCC GROL-licensed technicians. At Phoenix Air General Aviation, we are proud to announce that, with the exception of administrative and apprentice positions, every avionics technician who performs maintenance on your aircraft will hold their FCC GROL license.

25 years ago, Cirrus Aircraft re-imagined personal aviation with the SR Series. It redefined performance, style, comfort, and safety. But it didn’t stop there. In 2016, they ushered in a new era in transportation with the Vision Jet – the world’s first single-engine Personal Jet™.

Each year, Cirrus Aircraft raises the bar with continuous improvements, like sophisticated avionics and luxurious interiors. And Cirrus continues to redefine safety through their unique flight training program, Cirrus Approach, along with a host of tools and services to help Phoenix Air deliver a world-class experience to our customers.

For over 25 years, the Cirrus team has delivered an aviation experience that is the pinnacle of innovation, quality, and safety to their customers. And they are just getting started.

Founded in 1957, the Aircraft Electronics Association represents nearly 1,300 member companies in more than 40 countries, including approved maintenance organizations specializing in maintenance, repair and installation of aircraft electronics systems in general aviation aircraft. The AEA membership also includes manufacturers of aircraft electronics equipment, instrument repair facilities, instrument manufacturers, airframe manufacturers, test equipment manufacturers, major distributors, engineers and educational institutions.

To educate, communicate, and advocate for aviation businesses around the world that manufacture, support, and install innovative technologies for flight.

Power safer and more efficient flight.

J.P.Instruments was founded in 1986 in Huntington Beach, California, USA. Its founder, Joseph Polizzotto, is now the current CEO. Joe was educated at Villanova University as a mechanical engineer, who started his career in the 1960’s at Pratt and Whitney Aircraft in East Hartford Connecticut.

There, he worked as a test engineer, measuring temperatures and pressures on jet aircraft engines. With the experience gained in thermocouple technology at Pratt and Whitney, he designed the Scanner™ in 1979, for his personal Cessna 172, which he purchased from Mattituck aviation.

Curious as to what his engine temperatures were, but unwilling to constantly rotate a switch to do so, the Scanner™ was developed along with the help of his Uncle, Joe Giannelli, and his current partner and VP at JPI, Larry Elbert.

Soon thereafter, when friends and fellow pilots saw the new instrument in the 172 plane for the first time, they all wanted one for themselves. Thus, several prototypes were built for friends, and JPI as a corporation, was born and took up its first office in Santa Ana, California.

Following the success of the Scanner™ came the EDM-500.™ The EDM-500™ was actually the predecessor to the EDM-700™ series, and in fact originated as an concept, while in the car on the way to Hollywood Florida, just before the “Sun n’ Fun” air show. However, the exact parameters as to how the EDM was going to record and display data took several years for its completion, in addition to a lot of customer and market input. In the meantime, the Classic Scanner ™ (which is still available for the budget conscious pilot) paid the bills and kept the company on its feet.

Nowadays, J.P. Instruments has added a whole line of reliable and cost effective aircraft instrumentation to its name. Among these are engine data management systems, fuel flow gauges, and GPS moving maps. Pilots and mechanics alike have come to know JPI for its high quality, good service, and utmost reliability.

CamGuard Aviation is a blend of high performance additives that fortify piston aircraft oils to provide the utmost in engine protection. Because of FAA regulations and costs, even the newest commercial aircraft oil technology is antiquated. CamGuard Aviation contains powerful multi-metal corrosion inhibitors that prevent rust and corrosion in infrequently used engines. Infrequent engine use can lead to rust pits forming on cam and lifter surfaces. This pitting can result in catastrophic spalling wear requiring a premature engine overhaul.